LKC UltraPure

Designed to meet the specific demands of the biotech, pharmaceutical and personal care industries, the LKC UltraPure non-return valve provide safe, easy installation and high, consistent quality.

UltraPure quality

LKC UltraPure is developed to facilitate safe and easy installation that ensures optimum integrity. This valve offer high and consistent quality and thorough documentation which meet the strict standards of the biotech, pharmaceutical and personal care industries.

High and consistent quality

LKC UltraPure valves are subject to rigorous quality control. Alfa Laval performs all incoming and outgoing quality control and inspections and closely monitors every aspect of the manufacturing process – from raw material sourcing to tolerance and surface finish inspection to packaging and labelling. Tolerances and all surface finishes, for instance, are inspected with calibrated equipment. This helps ensure the highest quality possible.

Completely documented

All equipment and components in the Tri-Clover UltraPure portfolio are supplied with Alfa Laval Q-doc, a comprehensive documentation package that provides full transparency of the entire supply chain, from raw material to final equipment delivery. This smoothes purchasing and installation procedures as well as facilitates qualification, validation and change control procedures. Based on GDP (Good Documentation Practice), Alfa Laval Q-doc covers every aspect of UltraPure equipment supply and provides customers with transparent and well-documented quality assurance of the sourced equipment.

The Q-doc package for LKC UltraPure comprises quality and manufacturing procedures, material certificates and full traceability. This attention to detail maximizes uptime and minimizes risk.

For more information about standards and certificates, please visit our BioPharm Portal.

Avantages du produit

- Installation sécurisée et simple

- Qualité élevée et constante

- Complètement documenté

Catalogue produits

Fonctionnement

Application

Tri-Clover® LKC UltraPure est un clapet anti-retour empêchant l'écoulement inverse dans un système. La conception du clapet UltraPure a été pensée et documentée pour répondre aux demandes des industries telles que les produits biopharmaceutiques et les cosmétiques.

Principe de fonctionnement

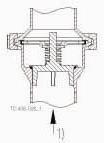

Le ressort actionne le clapet de la vanne, maintenant cette dernière fermée jusqu'à ce que la force de la pression d'entrée du produit soit supérieure à la force du ressort. Si une inversion de flux se produit, la force du ressort et la pression de sortie maintiennent le clapet fermé.

Conception standard

Le corps de vanne est constitué de deux parties assemblées par un collier clamp. Le clapet est constitué d'un disque muni de quatre tiges qui le guident alors qu'un ressort le maintient plaqué sur le siège du corps de vanne.

1 = Sens de l’écoulement.

Montre la position d'intégration optimale pour s'assurer que la vanne est bien vidangeable. Les quatre doigts de guidage du cône du clapet assurent un alignement correct.