Waste heat from Odense data center to warm local community

The leading social media giant aims to minimize the energy, emissions, and water impact, embracing the responsibility and opportunity to impact the world beyond their operations.

DATE 2024-07-09The opportunity

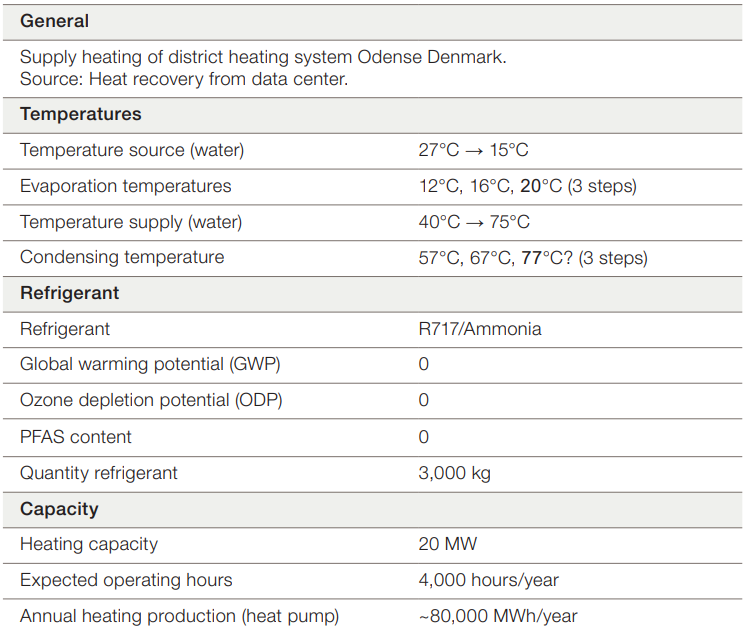

The construction of the new Odense data centre in 2017, was determined to be one of the most advanced, energy-efficient data centres in the world. The new facility features the latest hyper efficient hardware, cooled using outdoor air through indirect evaporative cooling technology and powered by clean and renewable wind energy. This facility is unique because of the infrastructure to capture and recycle the excess heat generated by the servers to provide heat to the local community.

The heated air from cooling the servers flows via water coils, recovering the heat by raising the temperature of the water. This water is then supplied to a newly constructed heat pump installation where the temperature is raised further and delivered to the district heating network and distributed to the local community.

The solution – sector coupling

Sector coupling was made possible by a partnership with the local district heating company Fjernvarme fyn. They were looking for new heat sources to phase out fossil fuels for the district heating of the city. A partnership was initiated. The local district heating company made the additional heat pump investment to recover the waste heat and will operate a new built heat pump station. A pipeline of cooling water circulating between the data centre and the heat pump station was established. The data centre proximity to the local heat distribution grid did minimize additional infrastructure connecting the heat pumps to the district heating network. The impact of the facility’s heat recovery infrastructure will help recover 100,000 MWh of energy per year – enough to warm some 7,000 homes.

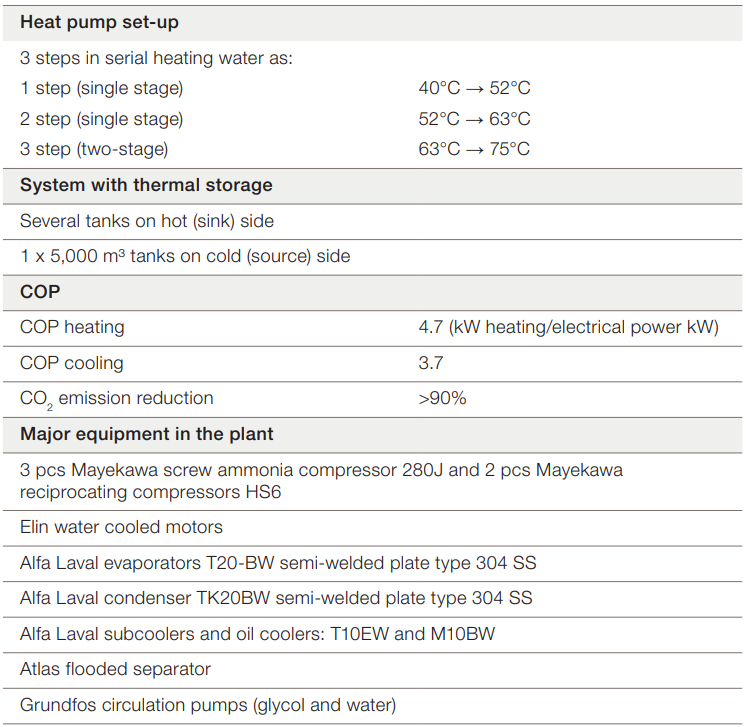

The heat pumps

The heat pump installations are made in three sections each supplying about a third of the total heat to deliver. IESenergy ApS delivered highly efficient industrial heat pumps designed in cooperation with leading main component suppliers such as Mayekawa (screw compressors) and Alfa Laval (semi-welded plate heat exchangers). The heat pump technology chosen is based on the latest development of industrial heat pumps avoiding F-gases and instead benefitting the efficient and future-proof natural refrigerant ammonia.

Alfa Laval supply and benefit

Alfa Laval is supplying the evaporators, condensers, subcoolers and oil coolers to the heat pumps. The impact of the facility’s heat recovery infrastructure will help recover 100,000 MWh of energy per year – enough to warm some 7,000 homes.

Energy savings

100,000 MWh per year

warm 7000 homes

Data center heat recovery, Odense