Large ammonia heat pump brings cleaned sewage water to heat local community

The installation of heat pumps at wastewater treatment plants has a huge, but rarely exploited, potential. The heat pumps can utilize the wastewater’s energy that would otherwise have been wasted and thus send greener and cheaper energy into the district heating system.

DATE 2024-07-25The opportunity, recover heat with large heat pumps

Heat pumps help us make optimal use of our resources and are also becoming a competitive green alternative to traditional energy technologies. We generally get more and more electricity from renewable energy. Heat pumps are then an important part of the energy system as they can produce district heating very efficiently, especially when there is a surplus of electricity, or the electricity is cheap.

This case is good example of sector coupling. Instead of discharging the treated wastewater directly into Odense river, it is since the end of 2020 led through a heat pump system that recovers the heat from it so the energy can be used for district heating.

Ramboll was chosen as consultant to design the new heat pump system at Ejby Mølle wastewater treatment plant. Ejby Mølle Wastewater Treatment Plant is owned and operated by the water utility company VandCenter Syd, while the heat pump plant itself is owned and operated by the local district heating company Fjernvarme Fyn.

The cooling process

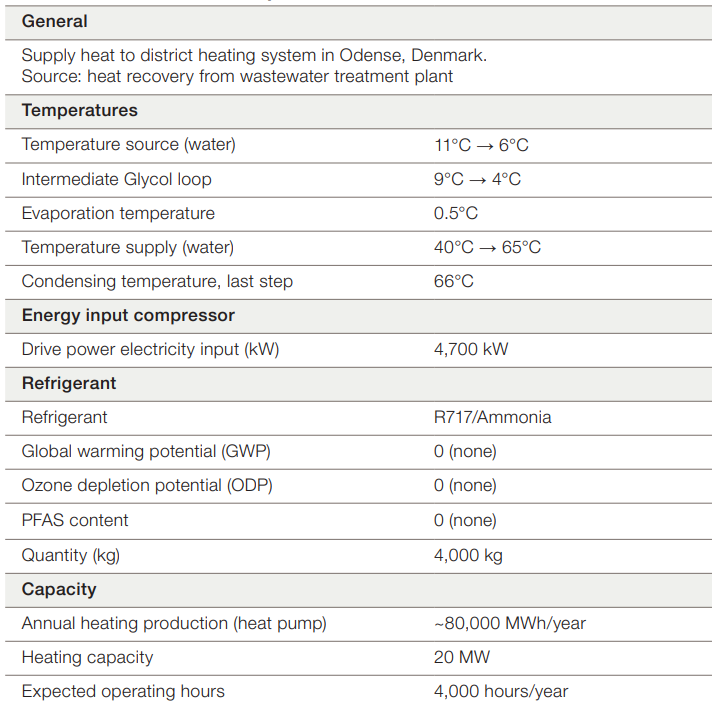

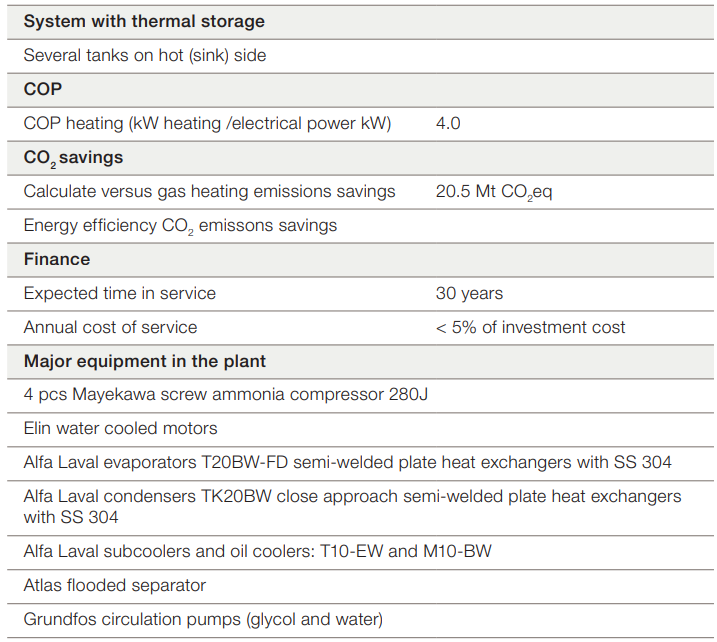

The heat pump consists of a closed system connected to both a district heating system and a wastewater system. The heat pump cools the treated wastewater by about 5°C using ammonia. Ammonia is one of the most efficient natural substances that can be used as refrigerant and it does not harm or heat the global atmosphere.

The cooling occurs when ammonia liquid at low pressure is passed through a heat exchanger. In the heat exchanger, energy is transferred from the wastewater to the ammonia circuit, causing the ammonia to evaporate. A rotary screw compressor then increases the ammonia pressure before the ammonia is condensed in yet another heat exchanger, from where the energy is delivered at high temperature to the district heating distribution network.

After condensation, the pressure in the ammonia circuit is lowered in an expansion valve before the liquid is led back to the evaporator. In short, the wastewater gives off heat that is fed into the district heating network and subsequently discharged at a lower temperature in Odense river.

An intermediate circuit has been added between the wastewater and the ammonia evaporator in the heat pump. Purified wastewater is usually 8-22°C when discharged, which is usually higher than the temperature of the water into which it is discharged. The closer to the creek’s temperature the wastewater temperature, the better. For large parts of the year, this heat pump installation will reduce the discharge water outlet temperature from the treatment plant to the water temperature of Odense River. When the temperature of the discharged water is more in line with the natural water temperature in the river, the aquatic environment is spared.

The heat pumps

The highly efficient, wastewater ammonia heat pumps were delivered by IESenergy Aps. They can produce approximately 4 units of district heating energy per unit of electrical energy consumed (COP = 4). The heat pumps at Ejby Mølle are thus a good step in the direction of a more sustainable heating. They can supply a total of 20 MW of heat and are expected to cover the annual heat consumption of at least 5,000 households. At the same time, the heat pumps will also lead to a reduction of CO2 and other greenhouse gases of 128,000 tonnes of CO2 equivalents over 20 years.

Alfa Laval supply

Alfa Laval has supplied the important and efficient reliable heat exchangers of semi-welded plate type. They operate as evaporators, condensers, sub coolers and oil coolers for these large heat pumps.

Wastewater treatment plant