Fuel cells

The transformation of the world’s energy systems is going to entail a wide range of solutions. Today we already know that fuel cells are going to be a fundamental part of our clean energy transition. As our global energy continues to rise, we will continue to need more – and more powerful – fuel cell technologies. In the coming years, we anticipate that fuel cells will be used for everything from distributed power to power generation for the every-growing data center sector.

Whether it’s about polymer electrolyte membrane (PEM), solid oxide fuel cells (SOFC) or solutions for the marine industry, tomorrow’s fuel cell technologies will place high performance requirements on thermal transfer technologies. Thanks to 90 years of advancing the possibilities of plate heat exchangers, Alfa Laval offers both the knowhow and the solutions for ensuring strong resistance under the high temperatures and thermal stress found in these challenging applications.

Ready for tomorrow’s fuel cell challenges

Alfa Laval has spent decades developing highly efficient and robust plate heat exchanger technologies. From our fusion bonding technique that enables reliable performance at very high temperatures, to gas-to-liquid solutions that can handle extremely uneven flow requirements, we can offer unique technologies perfect for fuel cell development.

Contact us to learn about the solutions we already provide today for the fuel cell challenges you will encounter tomorrow. This includes our leading competencies in fuel cell stack systems, as well as our Alfa Laval AlfaNova plate heat exchanger built to handle high temperature resistant materials. We can also share with you some of the development work we have underway, including innovations in bonding heat transfer solutions that will offer ideal alternative for marine fuel cell applications.

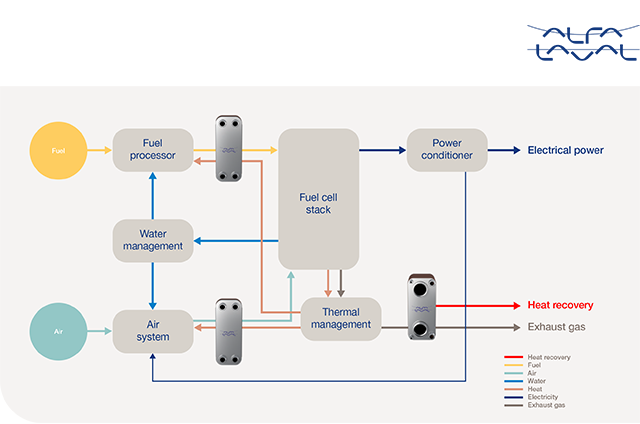

A fuel cell system built with Alfa Laval plate heat exchangers - Sustainable, safe and cost efficient

When the German renewable energy supplier HEE Technologies GmbH designed combined heat and power (CHP) fuel cell system, it was a clear choice to use Alfa Laval’s plate heat exchangers for fuel cell stack cooling and exhaust heat recovery. The system uses hydrogen as energy source, making it sustainable, safe, and cost efficient.

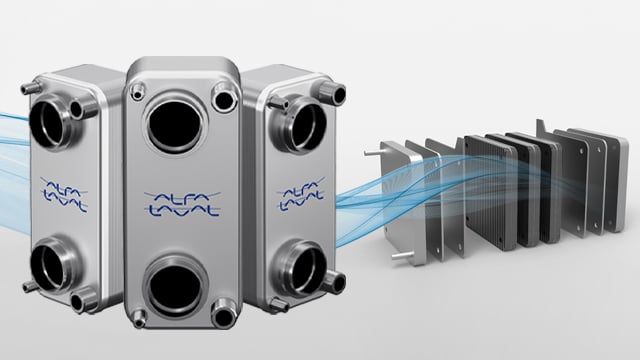

Meet the new AlfaNova GL50

The new AlfaNova GL50 is the first Alfa Laval heat exchanger developed for fuel cell requirements. The GL50 is an asymmetric gas-to-liquid plate heat exchanger made from 100% stainless steel. It is small enough to hold in one hand, but can handle gas flows of 250 cubic meter per hour, as well as inlet gas temperatures up to 750°C, with exceptional performance.

Our solutions

Alfa Laval brazed plate exchangers

Our copper-brazed plate heat exchangers are a compact, efficient and maintenance-free solution for heating, cooling, evaporation and condensing in numerous applications. Each unit is designed for duty optimization, with a range of unique features that ensure both superior thermal performance and maximum reliability.

Alfa Laval gas-to-liquid plate exchangers

From exceptionally high temperatures to media with extremely asymmetrical flow rates, Alfa Laval’s gas-to-liquid portfolio handles more than other plate heat exchangers. Built with a revolutionary “dimple” plate design, they provide efficient heat recovery and very low pressure drop in gas applications – all within a significantly smaller footprint than tubular technologies.

Alfa Laval fusion bonded plate exchangers

Our patented AlfaFusion bonding technology creates highly efficient, compact heat exchangers made entirely of stainless steel. Virtually maintenance free and capable of handling extremely high pressures and temperatures, they are an ideal heat transfer solution for challenging applications, including those with temperatures in excess of 600°C.

Energijos vartojimo efektyvumas

Švari energija

Tvari partnerystė

Susisiekite su mumis ir gaukite daugiau informacijos

Susisiekite su mumis šiandien, jei norite gauti daugiau informacijos apie mūsų tvarius sprendimus