Chelsea Sugar reduces carbon emissions with new Alfa Laval evaporation system

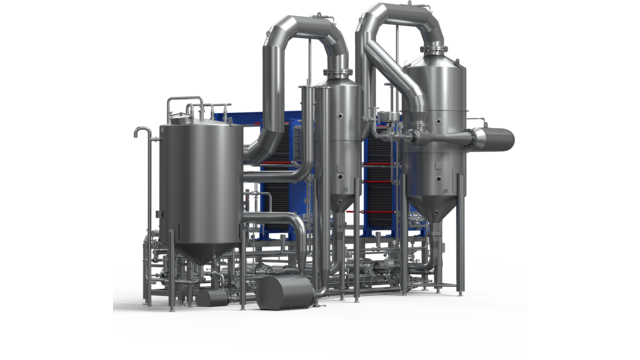

New Zealand Sugar Company (Chelsea Sugar) is a leading New Zealand manufacturer of natural cane sugar-derived products. To meet its sustainability and decarbonization goals, the company upgraded older thermal vapour recompression technology at its Auckland sugar refinery to a more energy-efficient Alfa Laval AlfaVap system, a rising film evaporator, with mechanical vapour recompression (MVR).

DATE 2024-03-21The result? A measurable increase in productivity, a 9% decrease in energy consumption and an 11% reduction in annual carbon emissions. Moreover, introducing Alfa Laval MVR technology makes it possible for Chelsea Sugar to incorporate renewable energy resources such as wind and solar energy into the plant’s energy mix, thereby cutting carbon emissions from sugar evaporation systems to near zero.

Our customer’s voice

Birkenhead, Auckland, New Zealand

Graeme Smith, General Manager, Operations ANZ, New Zealand Sugar Company (Chelsea Sugar):

“Today, one of our biggest challenges is that we must develop an increasingly sustainable operation and business, and the environmental impact of our sugar production is an important part of this.”

“Our relationship with Alfa Laval goes back many years, and it is the strength of our interaction and the mutual confidence in our competences, which has now enabled Chelsea to take on the journey in making the business even more sustainable.”

Top priority: lower carbon emissions

Optimizing plant operations through smart upgrades can help you meet your sustainability goals. Upgrading thermal vapour recompression technology to an Alfa Laval AlfaVap climbing film evaporator with mechanical vapour technology helped Chelsea Sugar contributed to greater energy efficiency, higher productivity, better product quality with minimal colour formation, and a reduced carbon footprint. Other advantages include:

- Solid return on investment

- Highly efficient and consistent operation

- improved control accuracy

- Minimal maintenance requirements

Click the link below to see how upgrading your evaporation systems can boost plant energy efficiency and decarbonize your operations.

How can we optimize your sugar refinery?

Want to increase productivity, realize energy savings, or enhance your sustainability credentials? Rely on Alfa Laval for expertise. We can help you optimize sugar refinery operations at every stage of production.

Selecting the right evaporation system depends on various factors, such as steam production costs and production volumes. Alfa Laval has a proven track record of delivering solid return on investment by engineering advanced evaporation systems using mechanical vapour recompression and thermal vapour recompression technologies. Mechanical vapour recompression systems generally are more energy efficient, have a smaller carbon footprint, and lower long-term operating costs compared to thermal vapour recompression technology. Contact us today to begin exploring new ways of enhancing operational efficiency at your sugar refinery.

Sustainable benefits

- By drastically cutting energy consumption in the refining processes, Chelsea Sugar reduces its plant’s carbon emissions by 11 percent which equals 2,767 tonnes of CO2 yearly.

- According to the UN, up to a third of the world’s carbon emissions can be attributed to food production.