Improve fishmeal quality with energy-efficient systems

Marine Functional Vietnam (MFC), a leading manufacturer of protein hydrolysates for food and animal feed additives, set out to increase its fish oil and fishmeal quality while cementing a leadership position in sustainability. MFC partnered with Alfa Laval based on its sustainability focus, broad equipment portfolio, and local service and support. The result? A 40% reduction in energy use, 80% reduction in odour emissions and a stickwater concentration up to 55% before requiring further treatment.

DATE 2023-11-28Efficient evaporation systems reduce energy consumption

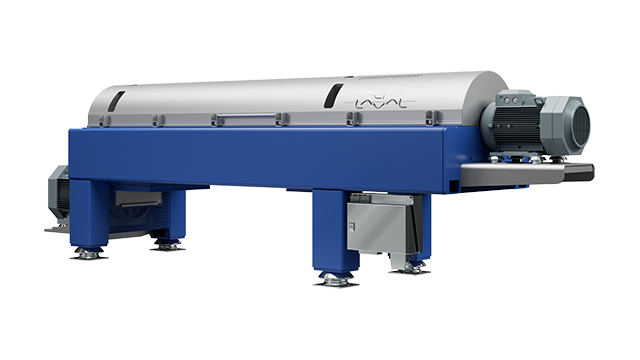

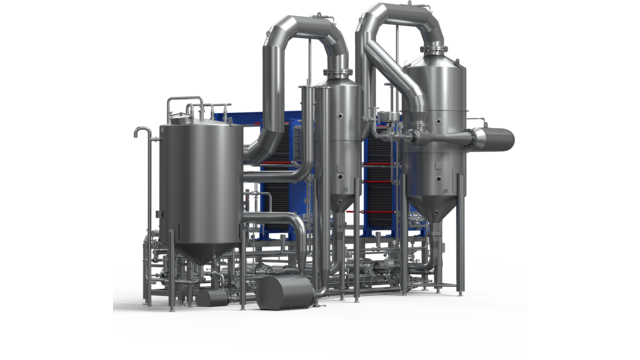

The plant processes raw fish into various products, such as fish oil and fish proteins, and converts byproducts into fishmeal for pet food, aquaculture feed or animal feed. Alfa Laval decanter and separators recover high-quality fish oil and suspended protein. Alfa Laval rising film evaporation technology then concentrates the remaining liquids before they enter a dryer to improve the steam economy of the plant.

“Alfa Laval has a solid reputation for delivering as promised and supporting customers throughout the equipment lifecycle. We were the first to work with Alfa Laval and install an Alfa Laval plate evaporation solution in Vietnam,” says MFC manufacturing manager Victor Tran. “The plate evaporator exceeded our expectations for energy savings, increased protein content, and higher quality and yield.”

It was quick and easy to install and commission the Alfa Laval AlfaVap evaporator since its compact footprint requires less floor space than conventional evaporation technologies.

Solid local support integral to business operations

Uptime is critical to the production process. Since the plant’s startup, a local Alfa Laval service and support team in Vietnam supported by regional teams has ensured maximum plant production time.

Sustainability is a mutual goal

MFC and Alfa Laval share a common vision for a more sustainable future. Like MFC, Alfa Laval believes that forging strong and lasting partnerships are vital to accelerating tomorrow’s sustainable solutions today. The Alfa Laval evaporator reduces energy costs for MFC by using waste heat from the dryer downstream to achieve a stickwater concentration of up to 55% compared to 40% for conventional evaporators. The higher concentration reduces the energy required to dry the fishmeal, contributing to MFC’s goal to cut its carbon footprint while increasing product quality. Both companies are strong advocates of using natural resources responsibly, improving energy efficiency and heat recovery, improving water treatment and reducing emissions, and minimizing the overall environmental impact of industrial processes.

Up to 40% in steam and fuel cost savings capturing and reusing energy from waste heat vapours from the drying process.

Increased fishmeal quality due to a stickwater concentration of up to 55% and shorter drying time.

Reduced carbon emissions and up to 40% in energy savings because the boiler requires less steam.