Sustainable heat recovery in compressed air systems

Improving the sustainability of industrial processes is a growing concern for businesses around the world, due to both increasing environmental awareness as well as the need to find new ways of reducing operational costs. In South Korea, for example, a number of major car manufacturers have put a renewed focus on heat recovery in their operations. Compressed air systems in particular have offered an area for new potential within sustainable heat recovery.

DATE 2023-11-28Numerous industrial applications utilize compressed air, but the energy needed to bring the air to the proper pressure (typically between 6-10 bar) typically warms the air by around 150-200°C. As a result, a heat exchanger is required to cool the air to a suitable temperature before it can be used in the system. Rather than simply allowing this heat to dissipate in the surrounding atmosphere, this creates opportunities to recover the energy for other processes.

In order to accomplish this, the right type of heat exchanger is necessary. To maximize the sustainability of the processes, the technology in question must be optimized to offer the greatest possible thermal efficiency for the duty. At the same time, it needs to be able to perform reliably while resisting the high pressures of the compressed air. It must also offer a compact design that can be flexibly and easily integrated into a variety of systems.

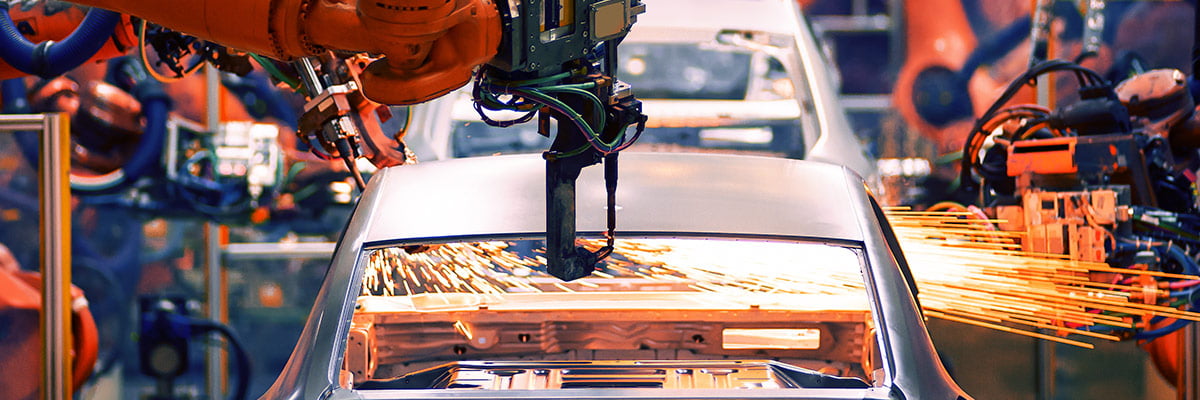

The compact design of

Alfa Laval gas-to-liquid heat exchangers makes them easy to integrate in compressed air systems,

as in this example from another auto industry leader in South Korea

High efficiency with a small footprint

Alfa Laval gas-to-liquid plate heat exchangers offer an optimal solution to these challenges. Built with a unique design that offers superior efficiency in applications with very disproportionate flow rates between the two media, they can cool the compressed air to temperatures just 5-10°C higher than that of the liquid medium. The liquid, typically water, can then be used for pre-heating or as valuable hot water in a wide range of other uses.

In addition to ensuring lower air-side pressure drop, Alfa Laval gas-to-liquid technology is also much more efficient than more traditional shell-and-tube solutions. It is also far more compact, with all connections integrated inside the unit and no additional pressure-resistant housing being required for dependable operation. This makes it simple to install for a variety of duties without increasing the footprint of the overall system.

Example specifications

Compressor fabricate: Samsung, IHI, Ingersoll Rand

Type: Turbo / Oil-free

Air pressure: 6 – 10 bar (a)

Air flow: ≈3 kg/s / 150 Nm3/min

Heat power: up to 300 kW

The Alfa Laval GL product line is an ultra-compact, high-efficiency solution engineered to meet the unique challenges of simultaneously working with gas and liquid media. A revolutionary new design handles very high temperatures with very low pressure drop.

Žymės

Visos