Cellular agriculture processing

Humankind has used fermentation to process food for more than 10000 years. The earliest examples include fermented dairy products and beverages. Over the millennia, people have invented a wide range of fermentation-based products – everything from red wine to sauerkraut and beer. Today, new fermentation processes are being developed to provide sustainable protein sources for a growing population, and Alfa Laval is taking an active part in this development with our cellular agriculture systems.

Increased interest in alternative protein sources

The development of new fermentation processes for food production has accelerated in recent decades. These new processes produce novel proteins and are an important step in the ongoing shift away from traditional animal-based protein sources.

The key drivers behind the growing interest in alternative protein are:

- A demand for more sustainable protein sources

- Requirements for less expensive food products and ingredients

- A growing population

- In many parts of the world people are shifting to a diet with more protein, and at the same time, many do not consume enough protein

- Massive sustainability problems in animal-based protein production, e.g. in terms of water and land use, deforestation, greenhouse gas emissions and waste

Investments in fermentation and cell-culture-based protein production methods have skyrocketed over the last years and in 2021 amounted to more than US 3 billion dollars, a figure that is expected to grow substantially over the coming years.

Processes for cellular food solutions

- Biomass fermentation – In biomass fermentation, the microorganism itself is the final product, and the fast growth and high protein content are leveraged to produce large quantities of protein efficiently.

- Precision fermentation – Precision fermentation technology uses specially designed microbial hosts that produce functional ingredients, such as proteins, oils/fats, and carbohydrates. The main difference compared to biomass fermentation is that the cells are not the actual product and are removed in the process.

- Meat production using cell cultures – This process is similar to biomass fermentation, but with the difference that animal cells from pigs, cattle, poultry, and fish are used instead of microorganisms, such as bacteria or fungi. This is a more challenging process as it requires a higher level of hygiene and a more complex feed and, in addition, the growth of animal cells is slower than for bacteria or fungi.

Alfa Laval provides equipment and complete production lines for all three types of cellular agriculture. Contact us early in your project to take full advantage of the support from our protein and fermentation experts. They can assist you with valuable advice during the design phase and help you select the right equipment based on your operating conditions.

Using Alfa Laval as a system supplier makes procurement easier, and it allows our engineers to finetune the performance of the entire processing line on a system level, resulting in benefits that are hard to achieve when using different suppliers for different parts.

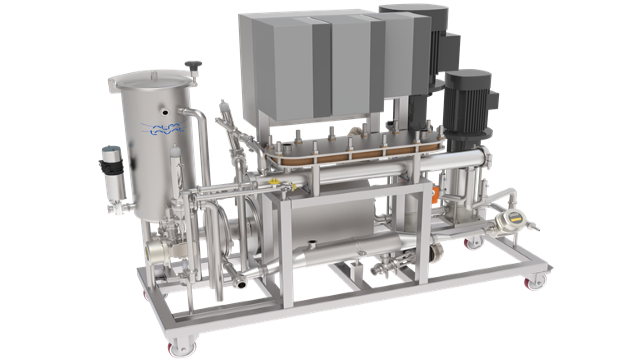

Solutions for biomass and precision fermentation, and cultured meat production

Capacity range: from pilot to full-scale production with a bioreactor volume of 1 to 200 m3 (44,000 gallons).

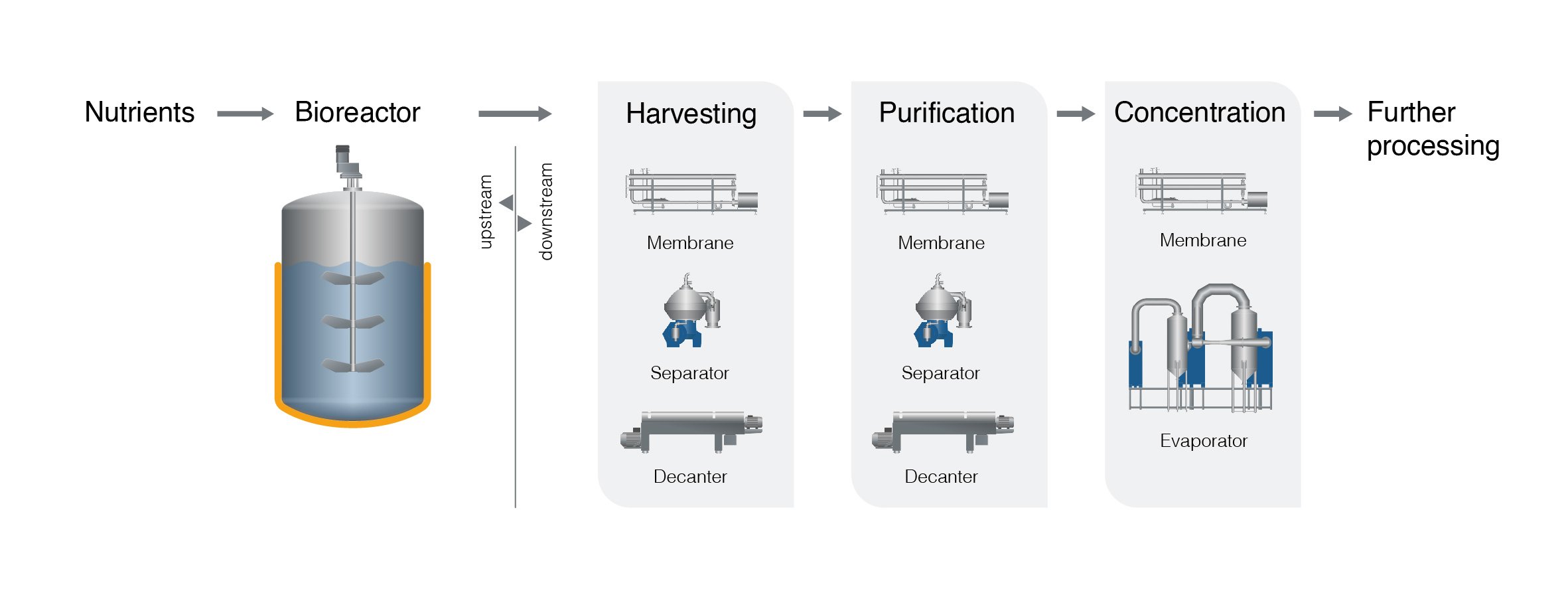

Bioreaction/Fermentation

- Bioreactors and fermenters for all types of processes and microorganisms

Purification

- Washing systems with separators or decanters

- Membrane filtration systems

At Alfa Laval, we have worked with customers in a wide range of fermentation applications for more than a century and can support you with both application knowhow and first-class equipment. We offer a full range of highly efficient upstream and downstream equipment for all types of cellular agriculture systems – biomass and precision fermentation, as well as cultured meat production – always fully customized to your requirements. We supply components, modules, and complete system solutions for pilot-scale systems to full-scale production lines.

All our products have excellent cleanability and hygienic design, and our proven CIP solutions ensure effective cleaning of the entire system.

We can also supply all the necessary auxiliary systems, such as:

- Fluid handling equipment, e.g. valves, pumps and piping

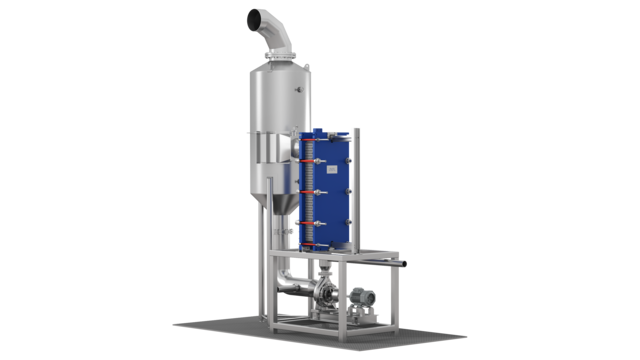

- Heat exchangers for heating and cooling

- Automation systems for easy operation and monitoring

Scaling up? No problem!

We are here to support your growth and development, and our application experts are glad to advise you on the best ways to industrialize your process as you go from pilot plant to full-scale production.

Thanks to a modular design, our cellular agriculture systems are easy to scale up when your business expands.

We are a one-stop shop for all your equipment needs, and in cooperation with our partners we can provide you with complete production lines.

Contact us to book a meeting where we can go through your process. We are more than happy to share our experiences from previous projects that we have completed.

Welcome to our test centre

We welcome you to make full-scale test runs at our test facility in Denmark. Here we have a complete setup covering all process stages, enabling you to try out new ideas and confirm the performance of various equipment.

If you prefer to make tests at your own site, we can provide test units, allowing you to test Alfa Laval products together with your existing equipment before purchase.

Sustainable solutions with low energy consumption

Minimizing energy consumption in your production line strengthens the inherent sustainability qualities in your fermentation-enabled alternative protein product, allowing you to establish a more attractive market position.

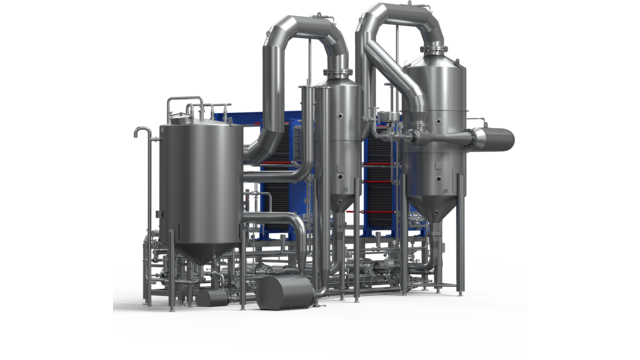

Using an Alfa Laval evaporation system for concentration is a straightforward way to save energy. These systems are based on highly effective plate heat exchanger technology, making them much more energy efficient and compact than shell-and-tube-based systems.

In addition, Alfa Laval evaporation systems are designed with multiple stages making it possible to reuse the heat several times in the system, thereby minimizing energy consumption.

Did you know …

- … that investments in fermentation companies increased almost 40 times between 2017 and 2021?

- … that investments in cultured meat production increased almost 70 times between 2017 and 2021?

- … that the majority of the investments are made in North America?

- .. that the first burger made of cultured meat was ready in 2013 and had taken two years to produce?

Complete service solutions

Combining a systems approach to service with extensive process expertise, we optimize the performance of your entire process by identifying and addressing the root causes of your issues.

We offer a complete range of services spanning the entire lifetime of your plant. Our global service network covers nearly 100 countries, meaning quick and professional support is always close.

For maximum return on your investment, we recommend entering an Alfa Laval Service Agreement. This fully customized service solution simplifies budgeting and maximizes performance and uptime. While you focus on your daily operation, we handle the planning, procurement and execution of the required service measures.