ACHE model G

Ensuring efficient and reliable cooling of your processes is key to staying productive and profitable. With ACHE model G for well-defined cooling needs, project execution has never been easier or faster thanks to the modular design, which ensures rapid ordering and delivery. ACHE model G can be used for general cooling duties in gas compression, downstream refrigeration and fuel gas compression applications.

ACHE model G is a modular air-cooled heat exchanger that provides reliable and cost-effective cooling of natural gas, water and/or synthetic oils — cooling duties that can be found around a natural gas compressor, for example. A flexible modular design allows the cooling units to be easily customized to the needs and options within ACHE model G’s design limits. ACHE model G has been designed by experts in the field — Alfa Laval Olmi — a reliable and well-known supplier of air-cooled heat exchangers to industry.

Modular design

To meet tight budgets and schedules, Alfa Laval’s engineering team has developed a modular air-cooler design. The modular design provides the flexibility to adapt to different conditions and requirements, while the pre-defined key parameters common to all ACHE model G units ensure a rapid ordering and delivery process.

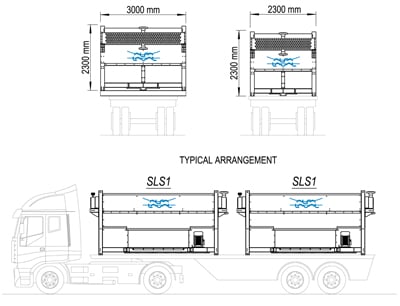

Designed for easy transport

Transporting air-cooled heat exchangers can be a timeconsuming and expensive exercise, especially if the units are oversized. All ACHE model G units can be transported on a normal truck or in a 40-ft container for convenient transport to the customer’s site by land or sea.

Benefits

ACHE model G is a modular air-cooled heat exchanger that is fast and easy to:

- Size and buy—pre-configured modules in flexible configurations

- Manufacture and deliver—pre-engineered blocks in compact design for rapid transportation

- Erect and install—bolt down the modules, plug in the power cables, connect the flanges and start

Kaip tai veikia

Three simple steps

With ACHE model G, you are only three simple steps away from plugging the unit into your system. This simple procedure not only reduces the time and cost of on-site erection, but also makes installation safer.