Emmie 2

This mobile centrifugal separator effectively removes both particles and water from oils widely used in industry. This dramatically increases oil service life, and reduces wear on all kinds of equipment.

The Emmie.2 mobile centrifugal separator system makes it easy and affordable to undertake highly effective cleaning of virtually any kind of service oil, including hydraulic and lubricating oil, compressor and gear oil, cutting oil and diesel oil. This system is the ideal way to clean oils used in relatively small installations because it is easy to move to wherever it is needed, as and when the need arises.

The Emmie.2 is a complete compact system that includes a disc stack centrifuge separator, feed pump and a PLC-based control system that makes it very easy to operate. The unit is installed in the bypass flow, so that no alterations to existing machinery are needed. Hooking it up is simple and straightforward, providing "plug-and-play" operation. The system works automatically and requires no supervision once started.

The Alfa Laval disc stack separator at the heart of the Emmie.2 system provide rapid, effective and continuous three-phase separation of water and particles, all at the same time. This system removes more than 99% of all solid particles 2–5 µm in size, and virtually all of the water – but none of the additives. It effectively removes any airborne dust, as well as particles that stem from wear on paint, metal, plastic or rubber. It also removes any water present, thus helping prevent key oil additives from oxidizing or decomposing.

Prolonging the service life of service oils increases uptime, reduces wear on equipment and cuts back on costs – to the extent that this compact go-anywhere separator normally pays for itself in less than a year.

Kaip tai veikia

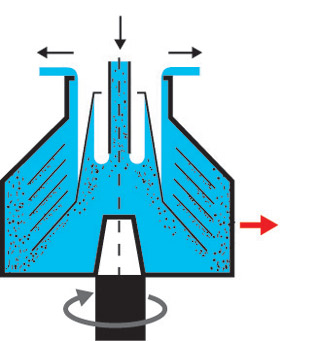

In a centrifugal separator, the gravity that causes separation in traditional settling tanks is replaced with a centrifugal force that can be more than 5,000 times stronger. Naturally, this makes separation significantly faster and more efficient.

If buffer plates are added to a settling tank, the sinking of any particles stops sooner, and there is a greater surface area onto which they will fall, helping speed up the separation process. In a centrifugal separator, the same basic principle can be applied, and a corresponding increase in effectiveness achieved, by a stack of special discs.

The centrifugal force presses any heavy particles present in the oil outwards against the walls of the separator, whereas any lighter particles tend to follow the liquid phase towards the centre. The disc stack prevents them from doing so, however, making the lighter particles change direction and end up with the heavy particles close to the outer wall.

This makes centrifugal separators an extremely effective way to remove solid particles many different types of service oil, as well as separating out different liquid components.