MIB

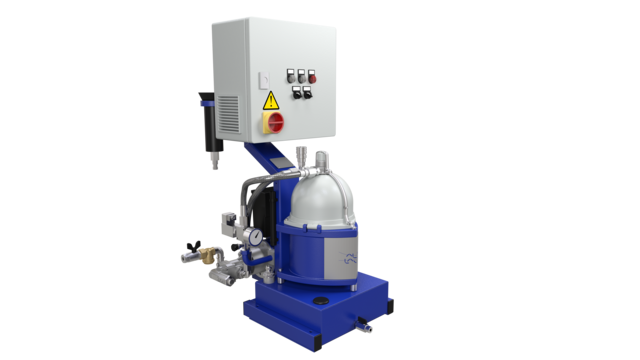

The MIB 303 separator features a new design concept for solid-bowl separators. Advanced manufacturing, design and drive technologies have contributed to a separator more compact and lightweight than conventional solid-bowl models.

The MIB 303 separation system is designed for centrifugal separation of sludge and water from mineral oil.The separator is designed for oils with a maximum density of 920 kg/m3 at 15°C. The maximum separation temperature for gas oil and marine diesel oil is +40°C, and for lubricating oil +70°C, since this is the max. separation temperature for the separator.

Features

-

No lock ring. Requires only small mechanical force on opening/assembling of the bowl.

-

New design allows the bowl wall to be taken out and cleaned with the disc stack still in place.

-

New lightweight materials in bowl and discs.

-

Direct drive with motor speed controlled by a frequency converter eliminates gears or belts.

-

Requires no lubrication.

-

The cleaned oil is discharged under pressure, due to the built-in paring disc pump.

-

Frequency converter with built-in voltage protector.

Available models

The MIB 303 separator is available as a purifier or a clarifier in stand-alone and module versions. There is also a choice between 230 V AC and 110 V AC. In the module version the ancillary equipment mentioned above is built together with the separator to form a compact unit

Benefits

- Easy to install, operate and maintain. No special training required.

- Small dimensions allow installation in narrow spaces.

- Removal of solid impurities extends intervals between filter replacements, which saves filter costs and reduces filter disposal handling.

- Removal of water from mineral oil improves the reliability of the oil system. It also reduces the risk of bacterial growth in tanks that could clog the filters.

- Electronics protected from voltage variations.

Kaip tai veikia

Mineral Oil

The MIB 303 separator in a cleaning system for distillate and marine diesel oil should be operated as a purifier. For cleaning of lubricating oil, MIB 303 purifier or clarifier can be used.

Throughput capacity

The MIB 303 separator has a throughput capacity of max. 760 litres per hour of diesel/gas oil and max. 460 litres per hour of steam turbine lube oil.

Standard equipment

Separator with drive, funnel for water supply with connections.

Ancillary equipment

Necessary for operation are: Starter for separator, feed pump with starter, collecting tank with water seal alarm, strainer, valves and fittings.

Separation procedure

Separation takes place in the rotating solid-wall bowl. The uncleaned oil is fed into the bowl where the centrifugal force makes water and solid particles move out towards the periphery of the bowl, while the clean oil flows inwards. To establish a water seal during start-up of the separator, water is added to the bowl before the oil feed is started. The water collects in the water seal which drains into the water channel below the bowl. The solids accumulate on the bowl wall and are removed periodically by hand. The cleaned oil flows towards the centre of the bowl and up to the paring disc. Since the oil is rotating, the stationary paring disc acts as a pump which forces the oil out through the outlet under pressure.