PureFerm

Get the most out of high-density cell fermentations with PureFerm bioprocessing centrifuges, featuring unique Alfa Laval technologies for continuous solids removal and gentle, foam-free treatment with up to 40% power savings compared to traditional top-fed centrifuges. High product recovery yield and low energy consumption makes PureFerm the ideal harvesting and purification solution for profitable next-generation food manufacturing.

Bioprocessing centrifuges with superior cell separation performance

- Efficient solids handling with continuous solids removal

- Up to 40% lower power consumption with Hermetic Design

- Hermetic Design minimizes shear for gentle cell treatment

- Bowl completely with fluid prevents oxygen pickup and foaming

- Easy operation: automated process control

Efficient cell culture separation poses significant challenges to profitable bioprocessing. The complex and delicate nature of cells requires careful handling to prevent damage or loss of viability. Scaling up the process while maintaining high productivity can become a hurdle, as filtration and other separation systems may not give satisfactory results.

Through continuous and highly efficient separation of large volumes, PureFerm centrifuges bring improved productivity to next-generation food and other bioprocessing applications. Drawing on unique Alfa Laval technologies such as Hermetic Design and Bactofuge – continuous solids discharge -, the PureFerm platform adds scalability, profitability, and unmatched energy efficiency to your process.

The PureFerm range

PureFerm centrifuges come in different sizes to meet your bioprocessing needs. All provide high-efficiency separation with continuous solids removal, gentle product handling, and minimized oxygen pick-up, together with low energy consumption.

PureFerm 250

- Max capacity: 10 000 l/h

- Small footprint, skid mounted separator with control system

- Easy to install and start up

PureFerm 750

- Max capacity: 25 000 l/h

- Modular design with control system

- Available with eMotion for added energy efficiency

Services

Įrangos našumo didinimas

„Alfa Laval" įrangos aptarnavimo paslaugos padės prailginti jūsų naudojamų sistemų veikimo laiką, maksimalizuojant procesų našumą. Tai leidžia jums:

- Nuolat tobulinti savo veiklą, kad išlaikytumėte konkurencinį pranašumą;

- Skirti dėmesį veikimo laikui prailginti, įrangos optimizavimui ir prieinamumui;

- Maksimaliai padidinkite investicijų grąžą per visą įrenginių eksploatavimo laikotarpį.

Kuo galime jums padėti?

Kreipkitės į mus su bet kokiomis užklausomis ar klausimais.

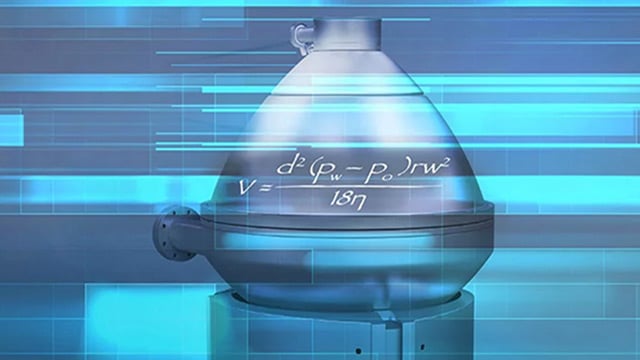

Better separation results with Hermetic Design

Hermetic Design is a proprietary Alfa Laval technology. It improves product handling and energy efficiency in a wide range of separation applications. The bottom-fed bowl filled completely with fluids enables gentle acceleration of media, with minimal oxygen pick-up.

Test, validate, and scale up your next separation solution

Whether upgrading your production line or running a proof of concept, Alfa Laval helps you choose the right separator solution with confidence. Simply get in touch to arrange a consultation and trial at one of our test centres, or to rent a unit for onsite testing.

Separation expertise for next-generation food

The world`s growing population deserves nutritious and tasty food, produced without harming our planet. The food landscape is changing, through groundbreaking research and cutting-edge technology. Alfa Laval provides unmatched separation expertise for this transformation: bringing scalability, profitability, and resource efficiency to next0generation food processes, like cellular agriculture.

Optiwia™: upgrade for water efficiency

Alfa Laval Optiwia™ is a standalone, plug-and-play water-saving upgrade for beverage production separators, designed to reduce water consumption by up to 70%. By reusing water for cooling, Optiwia minimizes costs, improves efficiency, and supports sustainable beverage production. Easy to install without needing connection to the control system, it ensures constant water pressure and solves yeast discharge issues. Upgrade to Optiwia for a smarter, greener, and more cost-effective beverage process.

"Separator Innovator

Ar norėtumėte sužinoti daugiau apie mūsų naujoves atskyrimo technologijų srityje? Spustelėkite toliau pateiktą nuorodą. "Alfa Laval" išrado pirmąjį diskinį kamino separatorių ir jau daugiau nei šimtmetį pirmauja centrifugų technologijų kūrimo srityje. Džiaugiamės galėdami pasidalyti su jumis patirtimi, kurią įgijome šiame kelyje. Apsilankykite mūsų žinių bazėje "Separator Innovator", kad sužinotumėte daugiau apie atskyrimo pažangą ir žingsnius, kurių "Alfa Laval" imasi siekdama tęsti technologijos revoliuciją.