Akutės ir apšvietimo priedai

„Alfa Laval“ akiniai yra tikslūs stiklai, leidžiantys tiesiogiai ir be iškraipymų tikrinti proceso sąlygas, produktus, skysčių kiekį ir valyti indus, naudojamus pieno, maisto ir gėrimų, asmens priežiūros ir biofarmo pramonėje.

Patikimai aiški žiūrėjimo kokybė

„Alfa Laval“ akiniai suteikia aiškų, nepertraukiamą ir netrukdomą procesų ar produktų matymą cisternose ar induose. Greitai ir lengvai montuojami „Alfa Laval“ akiniai užtikrina patikimą veikimą, mažus priežiūros reikalavimus ir ankstyvo aptikimo bei reagavimo priemones, kurios gali padėti išvengti brangių prastovų.

Matomojo stiklo konstrukcija ir asortimentas

„Alfa Laval“ matomojo stiklo asortimentą sudaro septyni skirtingi modeliai, sumontuoti arba suvirinti ant slėginių, neslėgtų ir aukštos temperatūros talpyklų ar indų arba vamzdžių sistemų.

Pagaminti iš borosilikatinio stiklo pagal DIN 7080 ir ilgaamžiai, specialiai suformuoti tarpikliai, šie matymo stiklai yra atsparūs skirtingiems slėgiams, temperatūroms ir gali būti naudojami įvairiems tikslams.

Norėdami gauti daugiau informacijos apie skirtingus akinių tipus, žr. Kaip tai veikia ir Dokumentacija.

Product Benefits

- Reliably clear viewing quality

- Provide clear, continuous and unobstructed visibility of processes

- Sight glass construction and range

Product catalogue

Kaip tai veikia

Construction

The construction of the Alfa Laval range of sight glasses varies, depending on the type of sight glass. For more information, please refer to the specific type below.

Sight glass DIN 11851

Typically used in tanks with high pressures and temperatures, this bolted sight glass consists of a base flange, which welded onto or into the tank wall, a cover flange, gaskets, a glass disc, nuts and studs. Provided that the flange is welded correctly onto/into the tank, the flange thickness guarantees a distortion-free location for the glass disc. The sight glass can be fitted with an optional miniVision light fitting.

Sight glass DIN 28120

The sight glass is engineered with a welding nozzle that is welded onto the tank wall, a grooved collar nut, a glass disc and two gaskets. The sight glass comes in sizes from DN50 (with a free view of 50 mm) to DN150 (with a free view of 150 mm). The sight glass can be fitted with an optional miniVision light fitting.

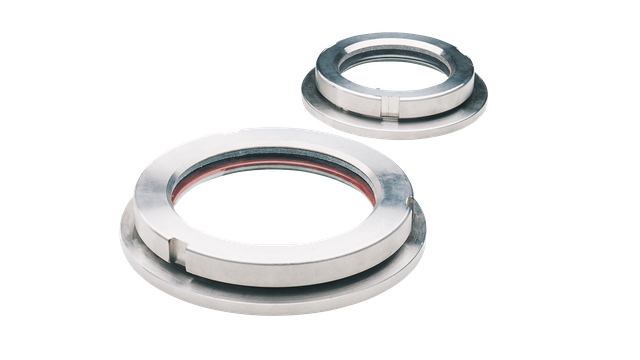

Sight glass types LKS 78, 105 and 120

Sight glass type LKS is available in three types. Sight glass type LKS 105 (free view: 105 mm) is designed for installation above the liquid level in pressure-less storage tanks. Sight glass types LKS 78 (free view: 78 mm) and LKS 120 (free view: 120 mm) are designed for pressure tanks. All LKS sight glasses consist of a threaded flange, which is welded onto the tank, gaskets, a glass disc and a retaining ring.

Sight glass Elongated

The elongated sight glass is used for the observation of the liquid level or reaction within the tank or vessel. It consists of a base flange that is welded into or onto the tank wall, a cover flange, a glass disc and gaskets.

Two versions of the Alfa Laval elongated sight glass are available.

· DB version has a base flange with bolt tappings drilled through

· SLversion has a base flange with blind tappings

Sight glass Metal-fused

Suitable for food processing and sterile applications, the Alfa Laval metal-fused sight glass is mounted on clamp fittings in accordance with DIN 32676.

Sight glass LKFL in-line

The LKFL in-line sight glass is used in processes that require observation of a product in a pipeline.

It consists of a tube with two screw connections for the glass. The connections are placed opposite each other to enable positioning of the glass very close to the internal wall of the tube.

An optional halogen light source, which is fitted onto one of the sockets, is available. The halogen light source consists of two stainless steel tubes assembled with a clamp.

The standard LKFL connections are welding ends. Upon request, the LKFL is also available with male part connections.

Sight glass LKG in-line

The Alfa Laval LKG in-line sight glass is used in pipe systems where a visual observation of the product flow is necessary. Two types are available: the LKGG-1 and the LKGL-1.

The LKGG-1 consists of a perforated stainless steel shield tube fitted with a welding union at each end. A special glass tube is fixed in the shield tube so that it is unaffected by potential stresses in the pipelines.

The LKGL-1 is similar to LKGG-1, but has a stainless steel light fitting welded onto the shield tube so that the product can be illuminated.