ACS

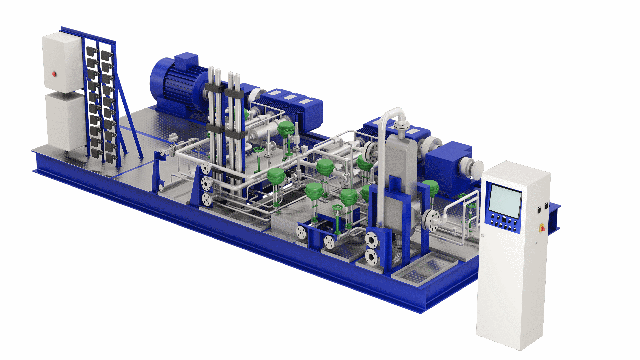

The FCM One Gas is an automated fuel gas supply system for the treatment of liquefied natural gas (LNG) to meet the cleanliness, pressure, temperature and flow rate specified by ME-GI dual-fuel engine manufacturers. Up to two high-pressure reciprocating pumps and one high-pressure vaporizer are included in a marine design suitable for installation in an ATEX Zone 1 area.

The use of ME-GI dual-fuel engines that are able to run on liquefied natural gas efficiently, sustainably and cost-effectively provides the marine industry with a viable solution to meet increasingly stringent emission control regulations.

Application

The FCM One Gas is designed for LNG conditioning in accordance with the pressure, temperature and flow guidelines of dual-fuel ME-GI engines. From cryogenic tanks at approximately -164°C, the LNG is delivered to high-pressure pumps that raise it to 250–320 bar(g) before it enters the vaporizer. The transition phase that takes place in the vaporizer is of particular importance. It is here that the cryogenic LNG reaches supercritical condition due to temperature and high pressure required by ME-GI engines.

Superior engine protection

The FCM One Gas offers unmatched engine protection through proper treatment of LNG and automatic routines that maintain constant dialogue with the ME-GI engines. These routines oversee the entire fuel conditioning process. All components (including heating and cooling components) are carefully selected and tested to ensure reliability and proper function.

Ease of use

The FCM One Gas is fully enclosed, fully automated and thoroughly integrated with the ship’s fuel gas supply system. Crews that have experience using other Alfa Laval systems will find its Alfa Laval Touch Control user interface familiar, despite the new fuel requirements.

The automatic cooling, start, stop, emergency shutdown and purging sequences are all controlled by Alfa Laval automation.

Safe operation

The FCM One Gas is an inline system whose major components are engineered for safety. Fully automatic control of the entire fuel conditioning process ensures protection of the ship hull structure from extreme low-temperature thermal shock. In addition, it ensures protection from LNG expansion and transient over-pressurization of the module interior during standby and stop sequences.

Flexible, modular arrangement

The design of the FCM One Gas benefits from Alfa Laval’s vast experience in designing marine modules to meet requirements for a minimal footprint and optimal maintenance space in hazardous areas.

Lowest possible operating costs

The FCM One Gas provides the lowest operating costs of any high-pressure fuel gas supply system available today. VFD-driven pumps and the use of the market’s most efficient vaporizer, the Alfa Laval printed circuit heat exchanger (PCHE), both contribute to its cost efficiency.

Related product

Alfa Laval Printed circuit heat exchanger

The Alfa Laval PCHE is a key component in the FCM Gas systems. With its unique patended design it delivers unparallell compactness and efficiency in high pressure duties, allowing design pressures from vacuum to 650 bar(g). Yet it is 80 % smaller and lighter than traditional shell-and-tube heat exchangers.

Global Service Network

Getting the best economy from your equipment requires getting the most out of existing resources. Alfa Laval has an extensive global network to help you do just that. With relevant innovations and limitless support, our peace-of-mind experts help you experience maximum uptime, availability and optimization.